Evaluation and Planning

Cleaning in the dairy industry is a critical process to ensure food safety and maintain required hygiene standards. Below is a detailed approach on how to carry out effective cleaning using industrial detergents, such as those we offer you in our detergent factory. In fact, we have specialized products such as our detergent Derlac 10Derlac 10 is a chlorinated alkaline product designed for efficient industrial cleaning. Its outstanding wetting and emulsifying power make it the ideal choice for the removal of organic residues, especially in heat exchangers. This product has proven its effectiveness in various sectors, from the dairy industry to the brewing industry, covering the entire food industry. Derlac 10 guarantees thorough cleaning and compliance with the highest hygiene standards, contributing to the maintenance of optimal sanitary conditions in critical industrial environments. In our catalogue you can find other cleaning products suitable for the dairy industry such as Derlac 20 or as DL 21 Chlorbac.

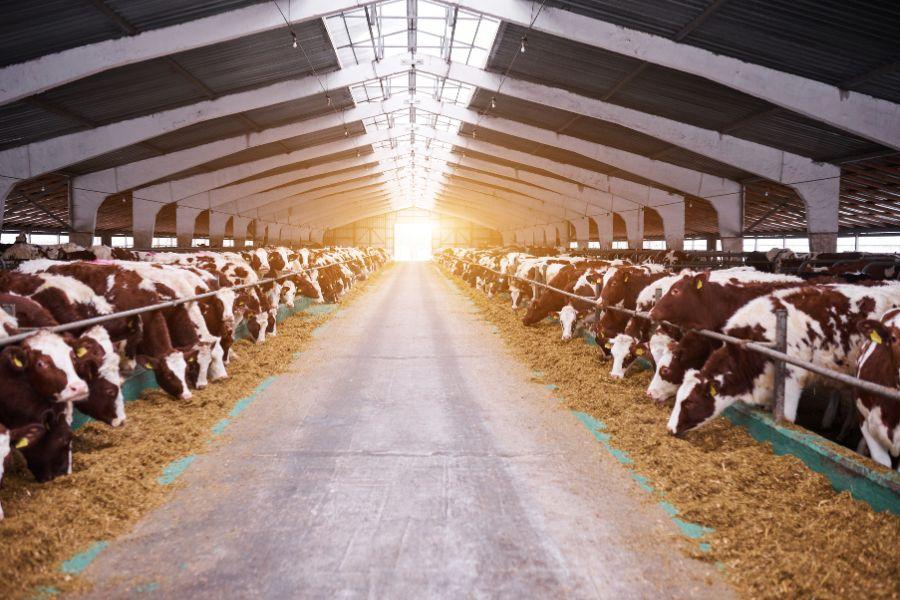

In the dairy industry, hygiene and cleanliness are critical aspects to ensure the quality and safety of products. As detergent factory We advise you to take into account:

- Strict Health Regulations: The dairy industry is subject to strict health and food safety regulations. Compliance with these regulations is essential to ensure the quality and safety of dairy products.

- Cleaning Equipment and Surfaces: Equipment used in dairy production, such as storage tanks, pipes and processing machinery, must be thoroughly cleaned to prevent bacterial contamination. Detergents and disinfectants specific to the food industry are essential.

- Temperature Control: Temperature is critical in the handling of milk and its derivatives. Strict temperature control must be maintained throughout the process, from milk collection to the production of final products.

- Preventing Cross Contamination: Avoiding cross-contamination is essential. This involves separating processing areas, implementing sanitation practices and ensuring that staff adhere to hygienic measures such as wearing personal protective equipment.

- Water Quality Monitoring: The quality of water used in dairy production is crucial. It must meet rigorous standards to ensure product safety. Regular monitoring of water quality is essential.

- Proper Storage: Milk and its derivatives must be stored at specific temperatures to prevent the growth of bacteria and ensure the freshness and quality of the final product.

- Staff Training: Staff must be adequately trained in food safety and hygiene practices. Ongoing training ensures that staff are aware of the latest regulations and best practices.

- Preventive Maintenance: Machinery used in dairy production must undergo regular maintenance to prevent problems and ensure efficient operation.

- Effluent Treatment: Proper treatment of effluents resulting from the process is essential to minimize environmental impact and comply with environmental regulations.

- Market Trends Tracking: The dairy industry must also stay abreast of market trends, such as the demand for organic dairy products or dairy alternatives, to adapt to consumer preferences.

The dairy industry requires a comprehensive approach that covers everything from production and processing to quality control and compliance with health and food safety regulations.

Detailed Cleaning Steps

1. Surface Cleaning

Start by cleaning the external surfaces of machinery and equipment with a quality industrial detergent. Pay special attention to areas prone to dairy residue buildup.

2. Equipment Cleaning

Use detergents specifically designed for dairy industrial equipment. Follow the manufacturer's instructions and focus on areas prone to grease and protein buildup.

3. Disinfection

Apply an industrial disinfectant after cleaning to eliminate any bacteria or germs present. Disinfection is essential when handling dairy products.

Ventilation and Odor Control

After cleaning, ensure adequate ventilation to remove any residual odor from cleaning products. This ensures a healthy working environment.

Regular Maintenance and Staff Training

Implement a regular maintenance program and provide ongoing training to staff on protocols and proper use of industrial detergents. Training is key to maintaining consistent cleaning standards.

By following these steps and using industrial detergents specialized in the dairy industry, efficient cleaning is achieved and meets the hygiene requirements necessary for the production of safe food. The key is planning, methodical execution and continuous commitment to best cleaning practices in this specific environment.